Company

Birth and Evolution

Tradition and innovation are the elements that mark the entire Beste journey, from its origins in 1992, when Giovanni Santi used his technical and creative knowledge to found a completely innovative entrepreneurial practice. Creating a new model of textile industry: strongly verticalized and integrated, aiming at the extreme innovation on fabric finishings.

Beste adopts the Organizational Model 231

Legislative Decree 231/2001 is an Italian law that regulates the administrative responsibility of legal entities, companies, and associations, even those without legal personality, for offenses committed in the interest or to the advantage of these entities. Legislative Decree 231/2001 identifies the Organizational and Management Model 231 as a fundamental tool to exempt a company from administrative liability related to offenses.

1992_Foundation

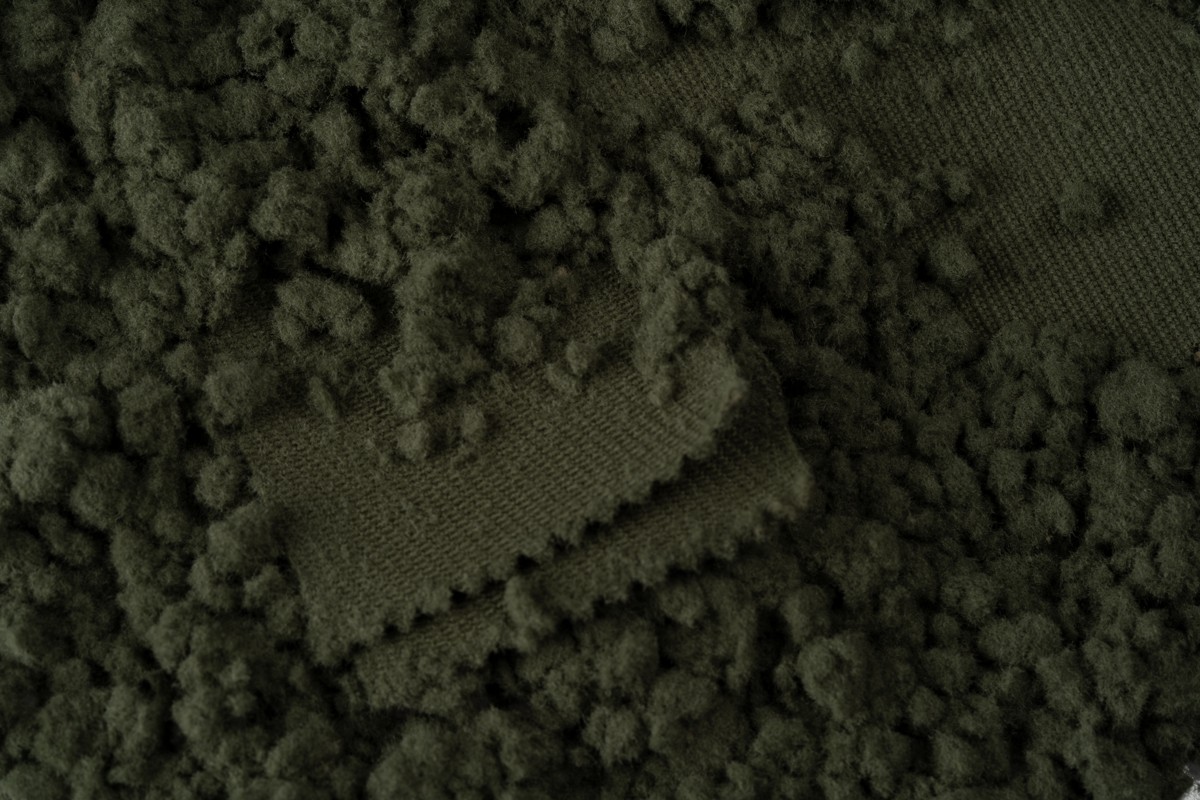

Beste was established in 1992 thanks to the determination and intuition of Giovanni Santi, a young fabric technician. After graduating from the Tullio Buzzi Institute, he received training as a textile designer and worked in some of the best textile companies in Prato. From the very beginning, Beste decided to revolutionize cotton production by using the machines at their disposal - ones used to treat wool. Their will was to combine a quality-inspired approach and the research of sophisticated solutions, aimed at transforming techniques traditionally reserved for the so-called “noble fibers”, like wool and cashmere, into those for cotton.

1995_Research & Quality

In 1995 we leave behind a modest factory to inaugurate a new location, where final product inspection equipment is installed. An innovative system of quality management is added to the advanced stylistic research. In 1997 Beste is amongst one of the first companies in the Prato textile district obtaining a UNI EN ISO 9001 certificate.

1995/2001_The big step forward

Around the turn of the millennium, Beste continues to grow at a steady pace. New collections are produced, new types of products undertaken (Bestech in 1995, Beware in 1998, Beste Jersey in 1999) and the company gradually makes its way into the high-end market. The simple initial structure is enriched with professionalism, namely employees overcome the threshold of thirty units. The time is ripe for a further quantum leap. Beste decides to take over the dyeing and finishing cycles directly.

2004_The new headquarters

After a long period spent renovating and adapting an old industrial complex, in 2004, Beste moves its headquarters to Cantagallo, fifteen minutes away from Prato. The whole textile production process is moved, as well as the commercial and creative departments. The direct control of the industrial process allows Beste to take another step forward on the road to quality. The company obtains the UNI EN ISO 14001 and EMAS certifications. At the same time the ownership was shared with the siblings of Giovanni Santi – Luca, Marco, Matteo, and Maria Grazia.

2005_From the fabric to the finished garment

In 2005, another decisive step takes place: Beste acquires the staff and know-how of a long established company specialized in high-end sportswear, acquiring twenty technical and creative employees as well as the brand Corpo Nove from Karada company in Empoli. In less than three years the new division doubles its turnover and soon becomes one of the cornerstones of the new commercial strategy. No longer a simple textile manufacturer, Beste is now able to systematically follow the entire design and production cycle through to any finished garment.

2006_The internationalization

With the aim of consolidating their relationship with the main markets and offering an exemplary service, a commercial reorganization strategy begins in 2004. It aspires to bring the company closer to its clients through a worldwide presence. The first step in this direction is the opening of B. Japan Co. Ltd. (Beste Japan), located in Osaka, Japan.

2008_Consolidation

Having concluded the production verticalization process, the company begins to search for stable industrial synergies. In Spring of 2008, these efforts materialized through the acquisition of Manifattura di Pontelambro, a well-established Lombardian company specializing in high-end shirts. The possibility to bring together the commercial and productive structures of the two companies spreads notable development potential and expands the repertoire of Beste group. A few months later Beste group acquires control of PWP, a prominent company on the Prato textile scene. At the beginning of 2009 the group expands further with the foundation of JIADA: more than a simple jersey line, it is rather a greater extension of the group.

2010_Production Reorganization

After a first season of acquisition and diversification, Beste faces new market scenarios with a profound rationalization of its creative and productive resources. A gradual transfer of all the responsibilities to the Cantagallo headquarters takes place, at the same time the direction of the multiple collections is entrusted to the designer Piergiovanni Donatucci.

2011_UpToBe

Beste decides to emerge on the market with its very own label, the project assumes the original emblem UpToBe and is constructed around the professionalism of Graziano Giannelli, the creator of important phenomenon such as Geo Spirit, Kejio and Peuterey. The initiative is accomplished through a partnership which entrusts Beste with the tasks of production, while Gianelli is in charge of product development, sales and distribution. This collaboration continues till the end of 2013 and terminates with the production of the SS14 Collection. Beste participation inside INCIPIT society – owner of UpToBe brand – stops indefinitely in 2014.

2012_Jointventure

Beste not only renounces its industrial calling and decides to shift its own dyeing and finishing know-how into a more competitive context. This turning point takes place in November 2012, through the agreement reached with Huamao company in Anqing, an industry giant of China hinterland specialized in natural fiber weaving. The agreement has the legal outlines of a joint-venture and is brought to fruition through the realisation of a modern establishment in China of more than 40.000 squared meters reserved for the Asian productions.

2013_Sezione Aurea

Beste reinforces the research contents and decisively chooses the direction towards quality, giving life to products strongly tied to the Italian context and bearers of exclusive features. Such direction is well defined by the textile line Sezione Aurea, debuting at the beginning of 2013. Over the months it expresses itself in terms of a fertile meeting ground with the world of leading brands and the most creative design, becoming a pure Made in Italy proposal of the luxury market.

2015_Strategic strengthening of the Garment Division

The internal garment laboratory is expanded both through the acquisition of special machineries (thermo-taping, laser-cut, ultrasonic machines, carousel press) and through the insertion of specialized personnel. This investment represents a clear strategic turning point: it corresponds to the will to acquire a more specialized physiognomy, a more direct involvement inside the production cycle, and a generally higher quality.

2016_The commitment to a sustainable development

The concepts of sustainability and social responsibility expand. After years of progress and evaluations on the ecologic front, Beste joins Greenpeace Detox Project by taking on the responsibility to eliminate - by 2020 - any sort of harmful substances for mankind and the environment both from its productive cycles and from its large supply chain.

2018_Tessuteka

The integration process between the Fabric Division and the Garment Division is strengthened. The company assumes more and more features of an ideal habitat where the internal and external project activity are able to grow and reach the market with products designed in any detail, with a production cycle totally under control, from the weaving to the packaging. From this highly creative orientation Tessuteka was born: a space that brings together three decades of history: over 13.000 different fabrics - developed in 26.000 color and finishing combos. These combinations are available for consultation according to various search keys by designers, researchers and students. Another key piece of that dialogue and collaboration platform that Beste is building with its increasingly international clientele.

2019_Bestone

After several years of experimentation, in the context of the Milano Unica trade show, Beste presents a tool that definitively consolidates its status as a company with regards to its creativity. Bestone is an application that lets you capture color – either with a normal smartphone or with a specific mini-scanner with a high fidelity – and to transfer them to a fabric database with to a wide range of options. It is an assist tool launched to the vast audience of creatives who can sample a color shade and instantly replicate it on fabric, choosing the format, the composition and the structure of the support.

2019_MONOBI

After years of experimentation and development Beste enters the B2C market with the MONOBI project - from the Japanese mono もの (thing) and bi 美 (beautiful) - proposing its first collection: a proposal of garments thought for the urban life with features derived for the outdoor world. Clean lines, specialty fabrics, great attention to detail and workmanship: the very special feature of MONOBI brand is the fully vertical and internal production chain, developed in just 20 KM and witnessing the complete transformation of the fabric into a finished garment.

2020_Carpini

A new expansive season opens for Beste: between the end of 2019 and the beginning of 2020 Beste acquires the historic Carpini brand: one of the wool collections that have marked the history of Prato textile district. An extra voice in the polyphonic choir of a group that is growing trying to sum up the vastness of the offer with specialist skills.

2021_BesteHUB

In September 2021, after a restoration in record time (less than five months to transform a building of the Seventies into a center with futuristic equipment) all the activities of the Beste group that involve the Garment Division - clothing development and production - are concentrated inside its new headquarters. This is not a mere logistic operation. This step forward expresses the desire - actually the necessity - to give a more precise identity to an area that is growing at a fierce pace with very specific needs and dynamics. Inside the new building is the product office, paper pattern office, the production office as well as a larger and better equipped studio that is not only housed, but also enhanced.

2022_Sutura

In 2022, Beste becomes a shareholder in the Sutura production plant with the intention of fully internalizing the entire production process.

2022_Texco

In 2022, Beste Group acquires the Texco wool mill, a historic Italian company known in the global textile scene for high-quality wool fabrics made from the finest noble fibers such as cashmere, alpaca, camel and yak. The acquisition of the leading wool production in the area represents the opportunity to expand the product portfolio to the fine wool category, materializing the commitment to innovation and excellence.

2022_Beredo

Since its inception, Beste has always declared its commitment to the environment, authentically and regardless of the certifications obtained. To sanction the authentic commitment to the realization of a business model capable of combining innovation and sustainability, in 2022 the Beredo project (from the union of Beste and re-do, in English do again and in Latin new) arises. In the perspective of an infinite circularity of textiles, Beredo operates a true regeneration process, which begins with the collection of textile waste and ends with the new introduction of fibers within the production process.

2023_Tessitura Serena

Tessitura Serena is a Prato-based company with 20 years' experience in the textile industry. In 2023, the Beste Group acquires its control, continuing to pursue the goal of implementing a vertical, controlled supply chain of the entire production cycle. With the acquisition of Serena's weaving expertise combined with the investment in state-of-the-art looms, Beste is now able to ensure the highest quality standards starting from the primary fabric stage. This operation again marks Beste's commitment to the renewal of its supply chain and the enhancement of the territory.

2023_Arca

Lanificio Arca was founded in 1950 under the vision of Cino Cini, an entrepreneur from Prato who, in the post-war period, created unconventional carded wool textile solutions for the time. After more than 70 years, Marco Cini, the heir of Lanificio Arca's legacy, maintains his grandfather's strong identity by keeping in operation a weaving mill consisting of 8 Jacquard looms and a showroom. In July 2023, Beste acquires Arca accessories and its related weaving mill with the prospect of internalizing another piece of the wool textile production. These looms indeed allow for production versatility ranging from handkerchiefs to typical fabric pieces.

Plan your visit to the company

Learn more about Beste and arrange a tour through its departments