Recycled categories

Every waste separated in raw could be regenerated according to various product type

(WOOL, CASHMERE ETC.)

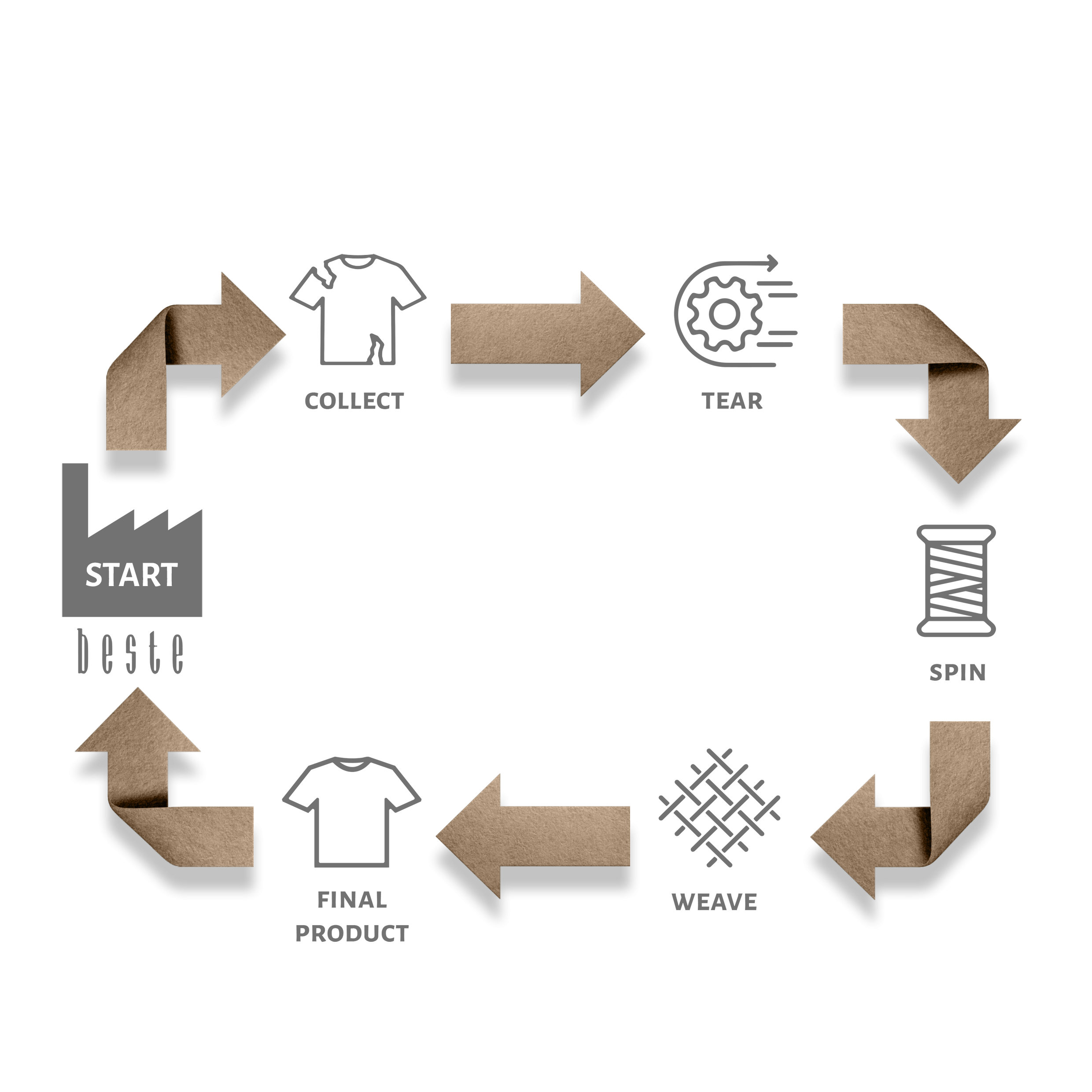

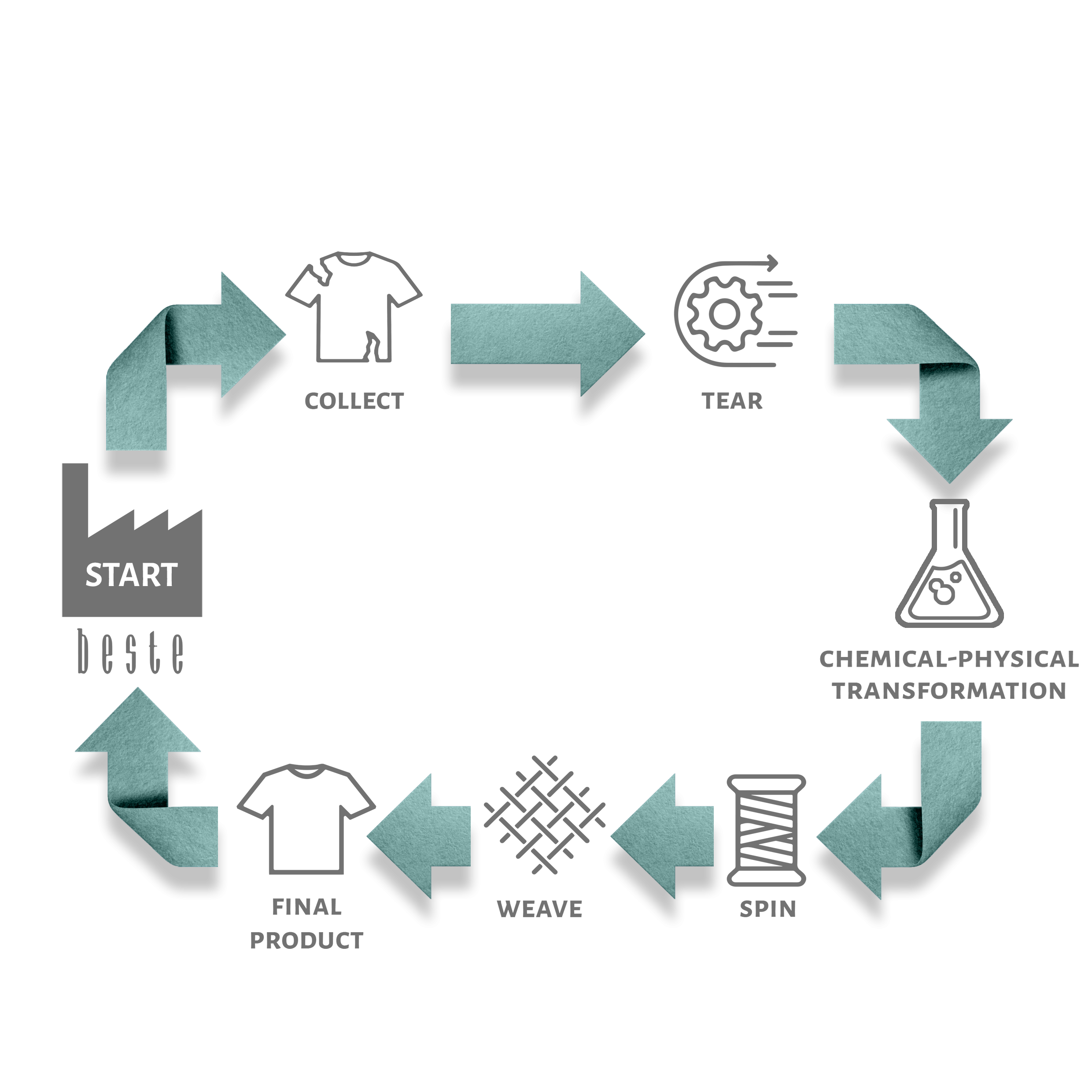

REGENERATION OF ANIMAL AND NOBLE FIBERS

The regeneration of cashmere, as well as that of all fibers of animal origin, is a typical practice of Prato textile district. Since the 1950s this activity has represented the heart of the local textile culture. The system leading to the reintegration of cashmere and noble animal fibers inside the textile production process begins with the collection of rags and production waste, sorted by color. Subsequently, the yarn structure is demolished and transformed into reusable fiber, for a new life cycle.

It is a sustainable production system that has always embraced the principles of circular economy inside the world of fashion.

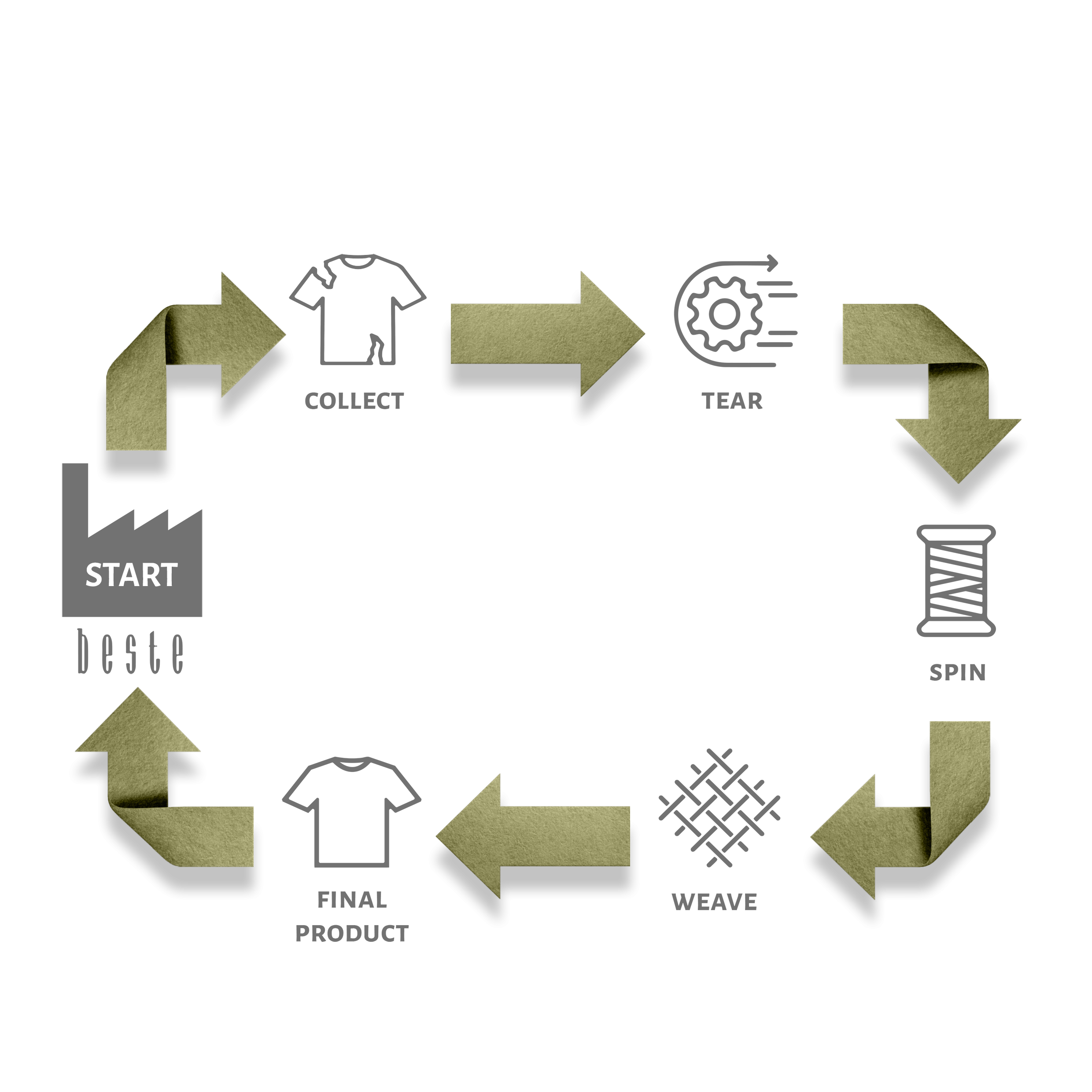

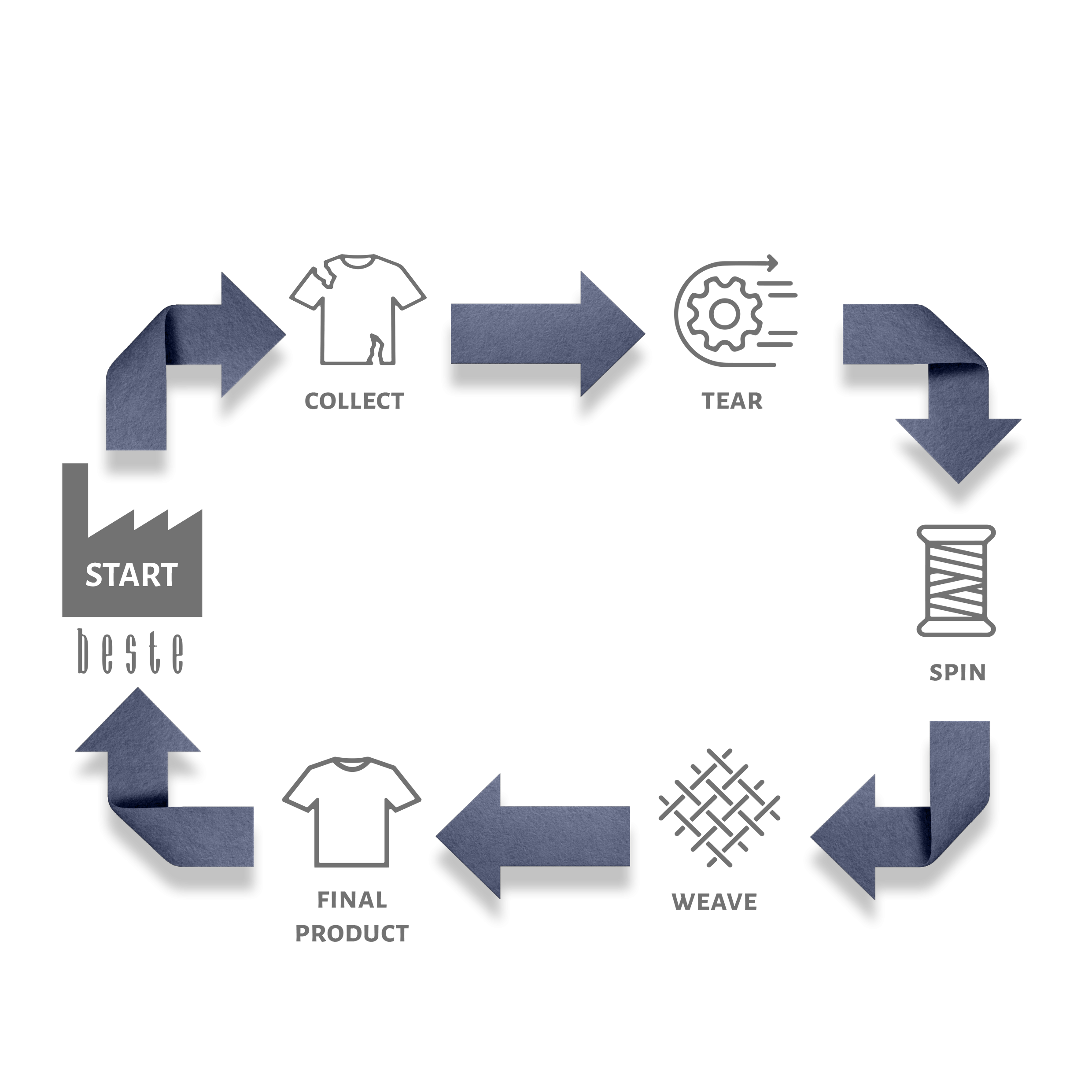

COTTON REGENERATION

When talking about cotton, the process begins again with the collection and division of scraps selected by color. In Prato textile district this process is carried out by the hands of workers called “cenciaioli”. Beredo, believing in this heritage, supports a project aiming at the reintegration of these professional figures by rescuing people coming from situations of labor and human exploitation. Subsequently, a particular shredding is carried out in order to preserve the length of the fiber.

In order to increase its resistance, the shredded material is hence mixed with virgin organic cotton material. This allows the yarn to obtain GRS certification and become suitable to make new fabrics and jerseys with different weights and structures. A sustainable regenerative process allowing resource saving too: the creation of a regenerated cotton t-shirt, in fact, only requires 30 liters of water, against the 2700 liters required for a virgin t-shirt.

Even the denim category can completely be recycled starting from processing waste and end-of-life garments, selected by indigo shades and thus able to generate incredible yarn colors suitable to recreate new jeans material.

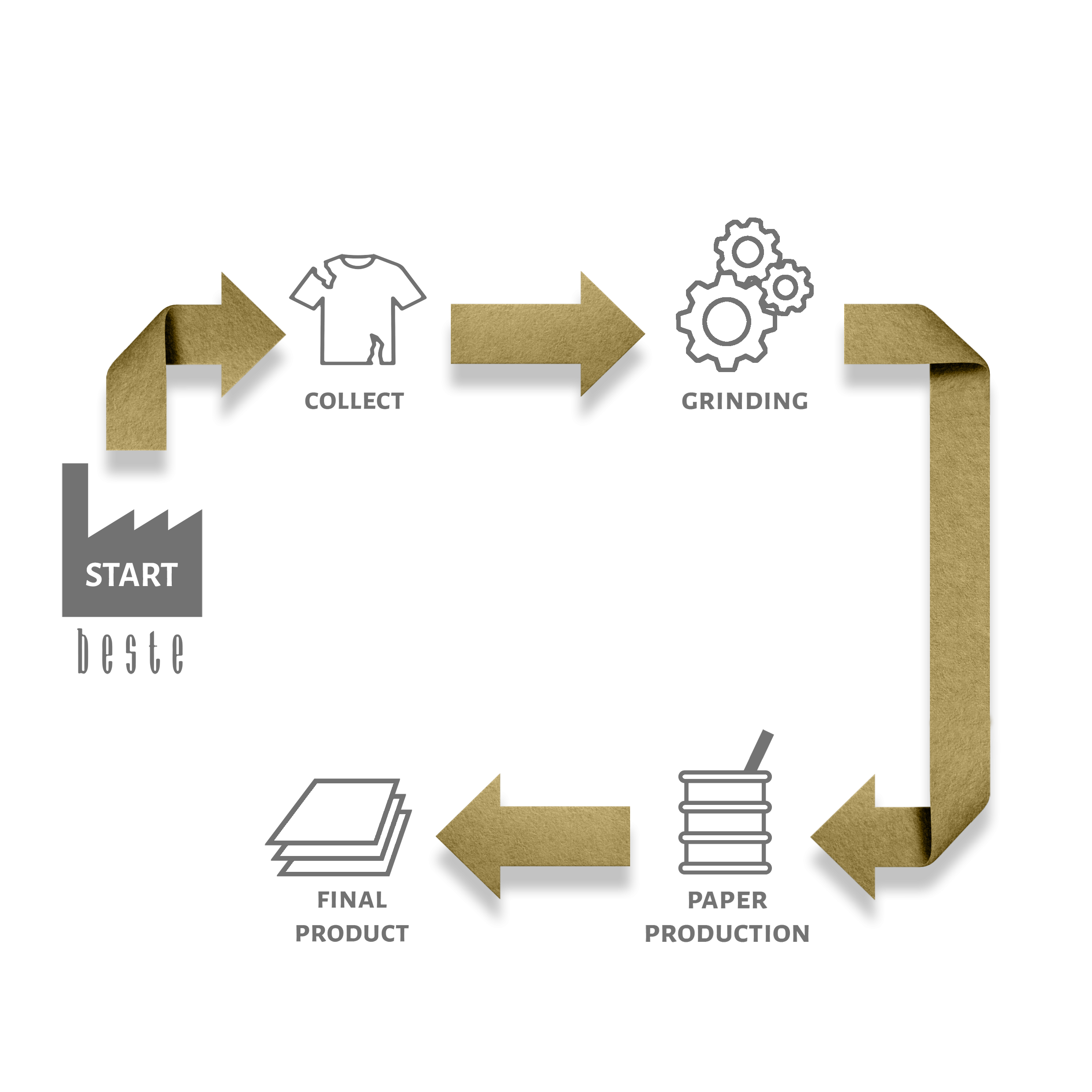

NATURAL PULVERIZED FIBERS: RECYCLED PAPER

Traditionally, paper is obtained from cellulosic textile rags, frayed and soaked in water. Thanks to innovative tools, Beredo is able to produce new raw material suitable for the paper industry coming not only from cellulose, but also from animal fibers and leather scraps. The result is new paper, caskets, boxes, customizable shopping bags, up to 50% derived from waste material.

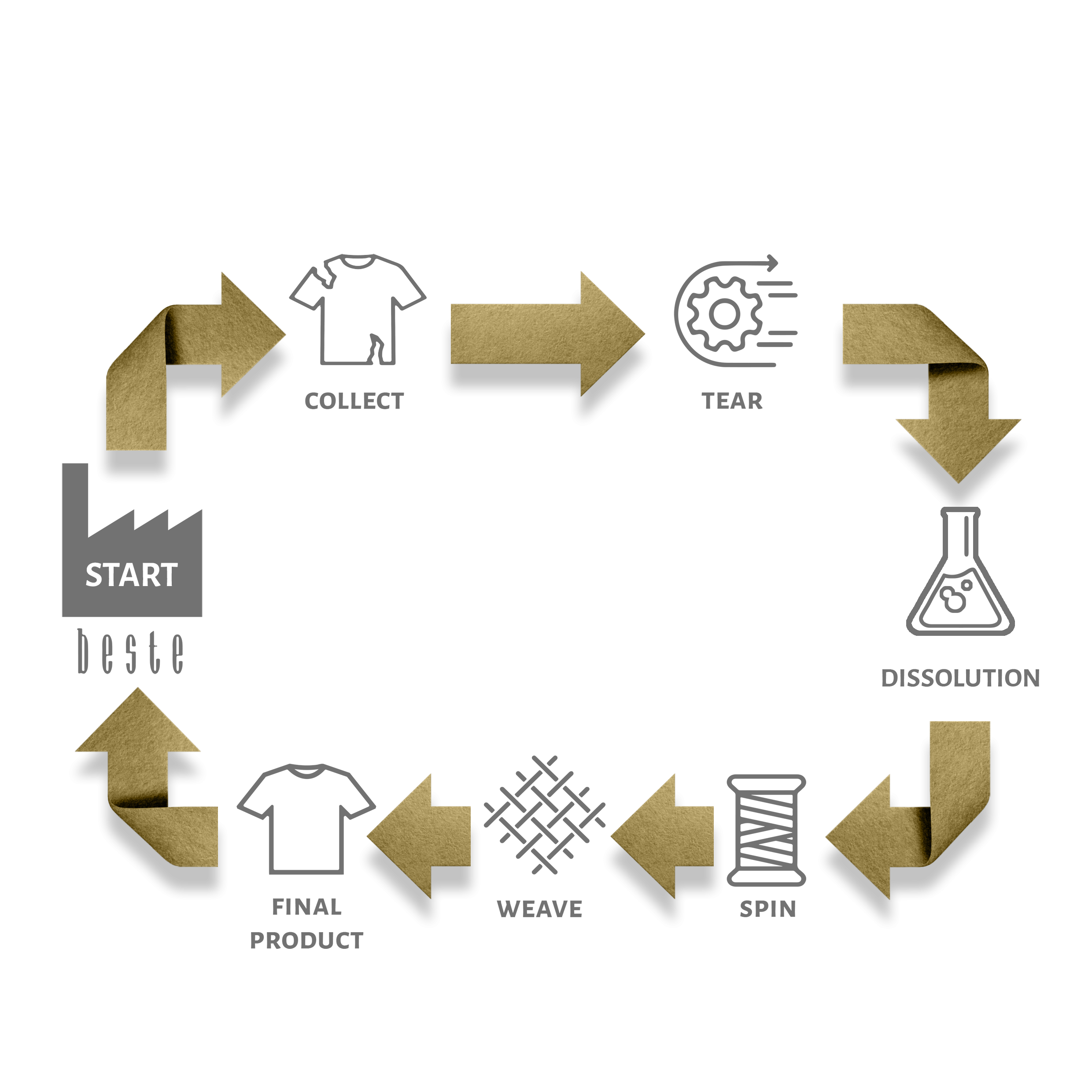

NATURAL PULVERIZED FIBERS: REGENERATED VISCOSE

Textile waste with a 100% cellulose composition can be transformed into “pulp”. The material coming from viscose textile rags is an alternative source to wood for the recreation of vegetable raw material. It is reused within the textile industry to reproduce viscose, lyocell, acetate and all other kinds of artificial cellulose fibers.

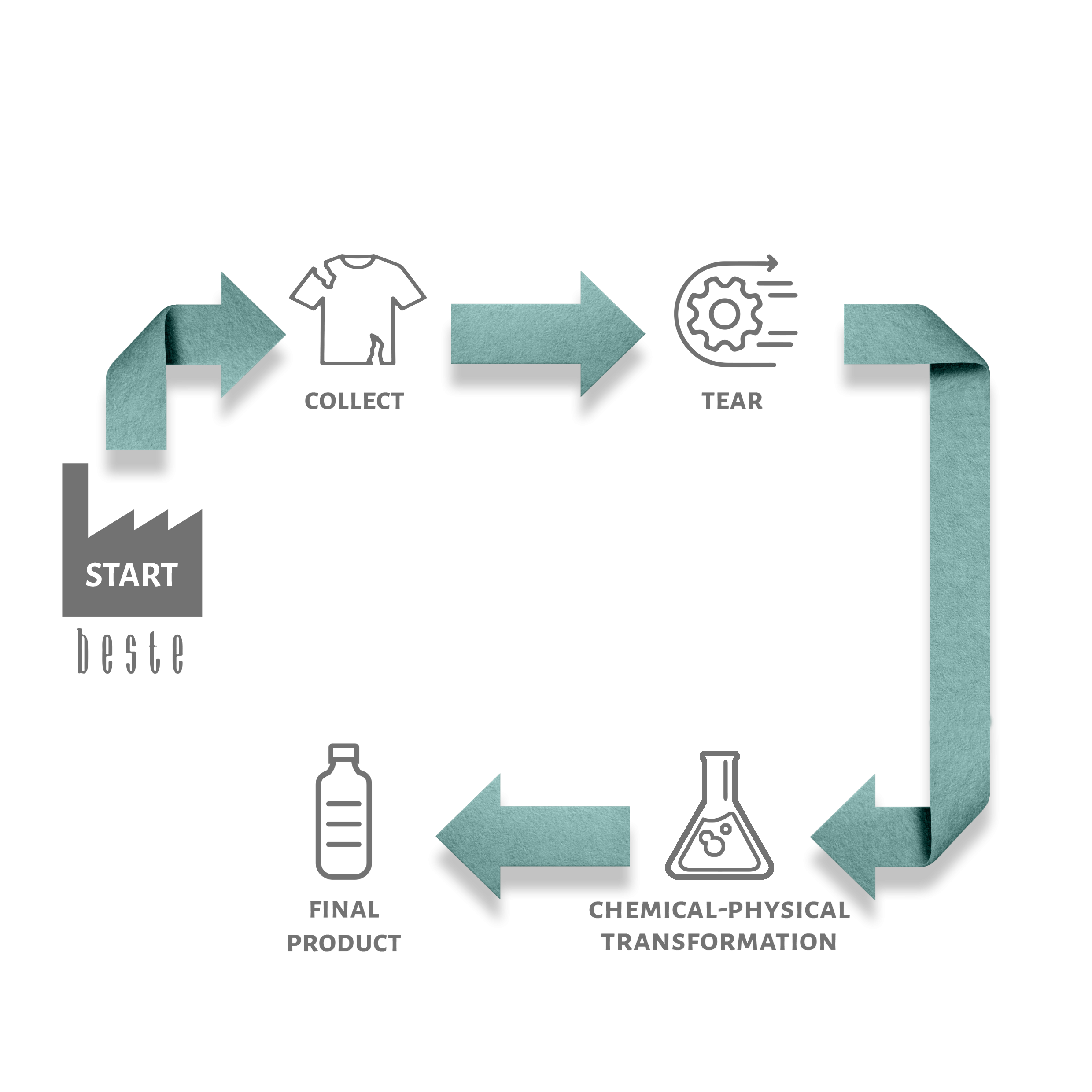

SYNTHETIC PULVERIZED FIBERS

Our polyamide fiber waste is recovered and regenerated through a complex chemical-physical process, rather than being disposed of. The product is exactly the same as its petroleum-based counterpart, except for the fact that it is entirely made from waste, without the aid of any further virgin raw material.

In this way, waste nylon is regenerated into new polyamide, employed to produce new textile fabrics.

RECYLCED POLYESTER

Our dependence on petroleum may be reduced through the use of recycled polyester: thanks to the pulverization of polyester fiber, it is possible to reuse production waste and end-of-life clothing in order to obtain new raw materials having multiple uses - including that of creating recycled plastic materials of various types.

REGENERATED SILK

Regenerated silk may both derive from staples or from the material reduced to powder. In both cases it is possible to generate new kinds of semi-finished products: carded or open-end yarns suitable for the regeneration of new fabrics.

Recovery is not only possible for yarn-dyed and piece-dyed materials, but also for printed and personalized ones, since the destruction process of the fabric makes any design or logo previously visible on the fabric unrecognizable.

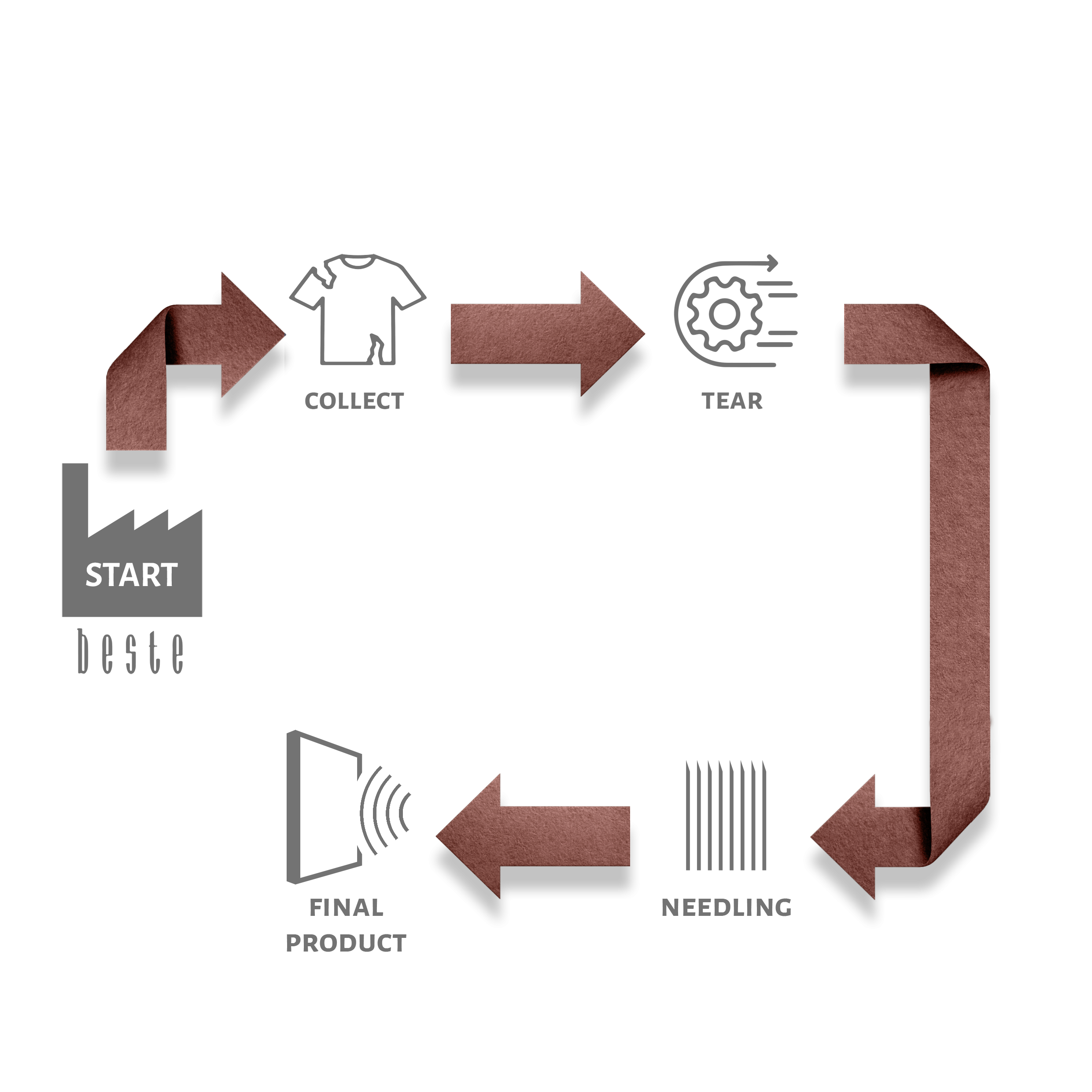

MIXED MATERIALS (“ROSSINO”)

The otherwise unrecoverable mixed fiber waste is transformed into thermo- acoustic panels used in the automotive industry for internal insulation and seat padding. Heat and pressure are the tools to create this kind of material that comes in the form of blocks.

Thanks to this practice, all waste that would otherwise be burned into incinerators can now be recycled and have a new life.