THE FIRST

THE FIRST ITALIAN ORGANIC COTTON

BESTE presents ITACO, for full control of the cotton supply chain entirely within Italy. From cultivation to production, ITACO ensures 100% organic and traceable cotton, strengthening our commitment to excellence. A decisive step toward reinforcing relationships with global supply chains and promoting true Made in Italy.

ITACO™ Experience: a journey into the world of Italian organic cotton

PUGLIA, IT

The ITACO™ Experience is an immersive journey into the heart of our ITACO production chain, beginning with Italian organic cotton fiber and continuing through the initial stages of processing, including ginning.

In the heart of Puglia, visitors enjoyed a deeply engaging experience that allowed them to connect directly with the land and with the people who bring it to life every day. They had the opportunity to witness firsthand the work of the farmers and operators involved in the project, gaining in-depth insight into each step of the production process from the most tangible aspects to the more technical and innovative elements of the supply chain.

ITACO'S CULTIVATION

ITACO'S SPINNING

PUGLIA, IT

100% Italian organic cotton by Beste

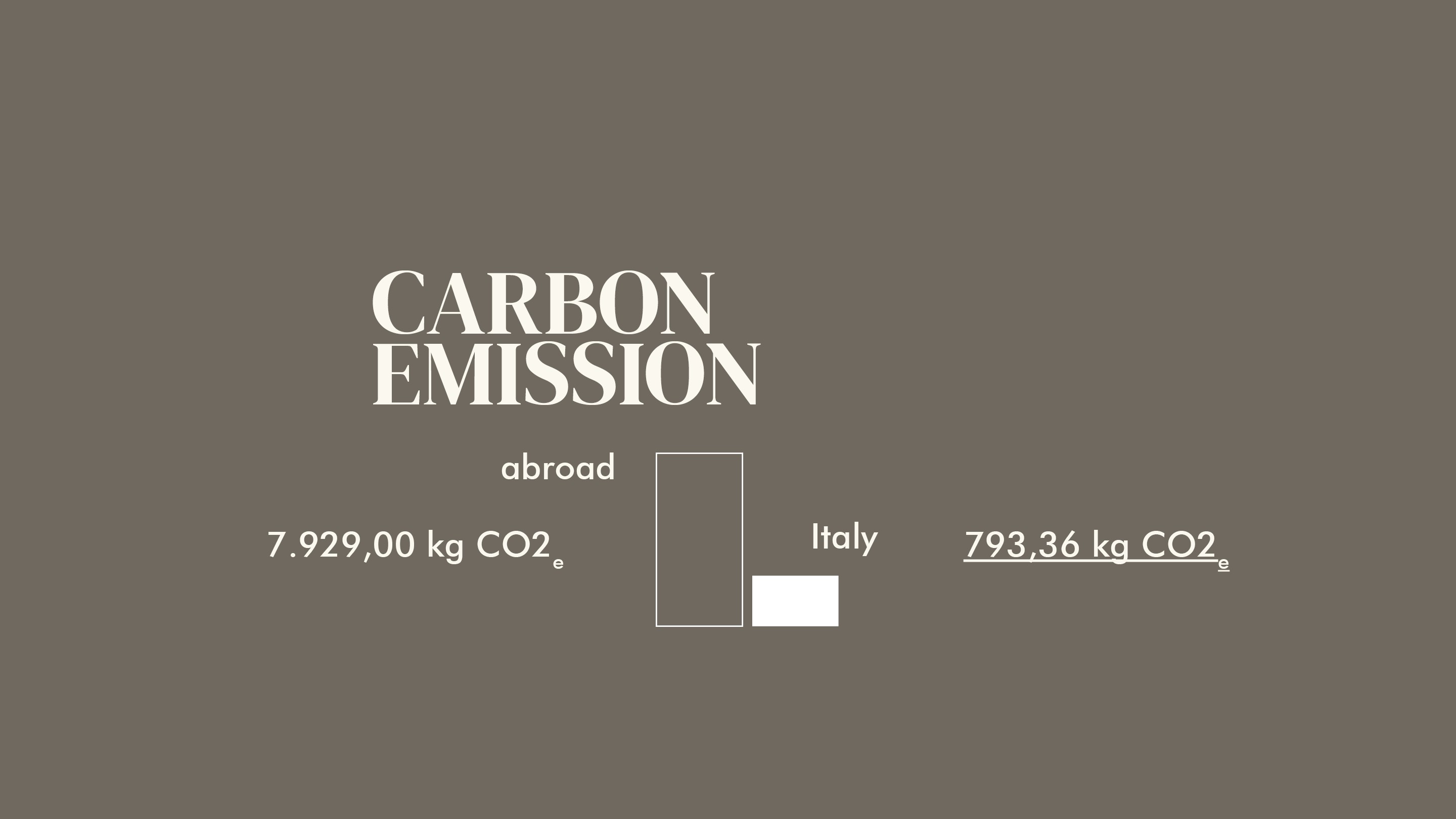

Beste has embarked on a revolutionary initiative in controlling the textile supply chain from the raw material. ITACO™ is a new project, created from 100% Made in Italy tracked organic cotton.

In view of a fully European production perspective, Beste has decided to report the complete supply chain in Italy for the creation of Made in Italy fabrics and garments. The cultivation, abandoned in the 60s due to the advent of synthetic fibers, was also revived thanks to the support of Coldiretti who together with Beste made a new and unique supply chain possible.

PUGLIA, IT

Ginning Facility

The ginning of cotton is a crucial phase in the processing cycle of the raw material. During this stage, raw cotton is cleaned of impurities such as seeds, branches, and leaves using machines that separate and open the fibers. This ensures the production of clean cotton fibers, ready for the subsequent stages of yarn manufacturing.

Beste is investing in a new ginning facility — the first of its kind to be established in Italy as part of the ITACO project. This investment aims to revitalize cotton cultivation in various Italian regions. The facility will not only enhance local production but also significantly reduce the time between processing stages, as it is located close to the cotton fields.

In addition, the ginning plant will recover the seeds, which will then be selected and crossbred by a breeder. Through simple seed pairing, the fiber yield will be improved year after year.

BERGAMO, IT

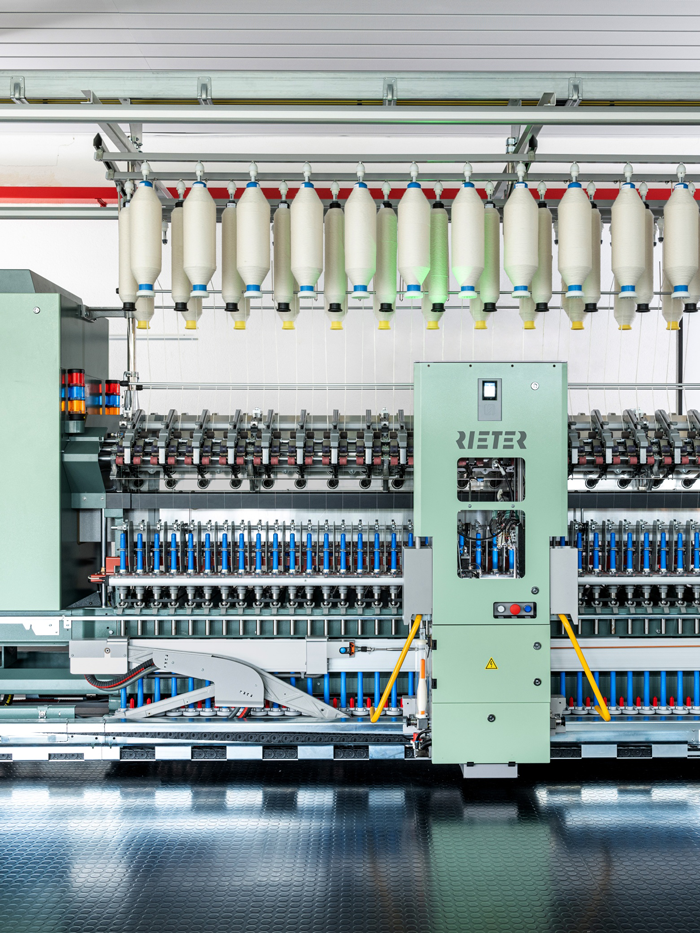

Italian spinning mill

The spinning of cotton in Italy takes place through a strategic partnership with a primary company in Northern Italy: as an example of an authentic re-shoring phenomenon, Beste reconvert to Italy the spinning process through the implementation of a factory that will be partially converted to Cotton spinning spinning with a mix of strong automation plants and machinery that will work the cotton grown in Italy (ITACO™).

Beste Weaving

PRATO, IT

Tessitura Serena

Tessitura Serena, a company part of the Beste group, transforms ITACO™ yarn Italian cotton grown in Puglia into greige fabrics. With 22 looms and total process control, from selecting yarns to creating refined designs, Tessitura Serena ensures the highest quality standards. Through Serena, Beste successfully integrates in the textile production supply chain, adapting agilely to fabric variation and maintaining high quality standards.

PRATO, IT

Beste Dyeing

The Beste dyeing facility is a fundamental pillar of ITACO™ cotton supply chain. With automated dosing and advanced chemistry, it employs innovative methods and technologies to reduce the environmental impact while preserving the brilliance and stability of our fabric colors.

A vast assortment of colors and shades is available to meet customer demands. This phase, characterized by transparency and traceability, demonstrates a genuine and synergistic connection between the individual stages of the production chain.

PRATO, IT

Beste Finishing

The art of finishing is a fundamental phase of our textile supply chain, where craftsmanship meets innovation to create fabrics with unique characteristics. From the feel of the fabric, to the drape, to the elasticity without the use of non-sustainable fibers, all this is achieved through Beste finishing, which is a work of art. It is a guarantee of uncompromising excellence.

PRATO, IT

BesteHUB Assembly

At the Beste Hub in Prato, our Garment Division transforms innovative ITACO™ material into Made in Italy products. Established between 2004 and 2008, Beste Garment Dvision controls every aspect of production, from sourcing the finest organic cotton to crafting high-quality garments. Featuring a bespoke tailoring atelier, a rich archive for designers, and cutting-edge prototyping machinery, the Beste Hub is a vibrant space that blends tradition with innovation.

Recycle

Collect and Recover all textile waste

BESTE is taking a new direction by addressing the reality of recycling and actions aimed at reintegrating textile waste into the fashion production cycle or related sectors. The recycling of textile waste is a significant contribution to the development of a culture of environmental and social responsibility that Beste is nurturing internally and wishes to share with the companies it collaborates with